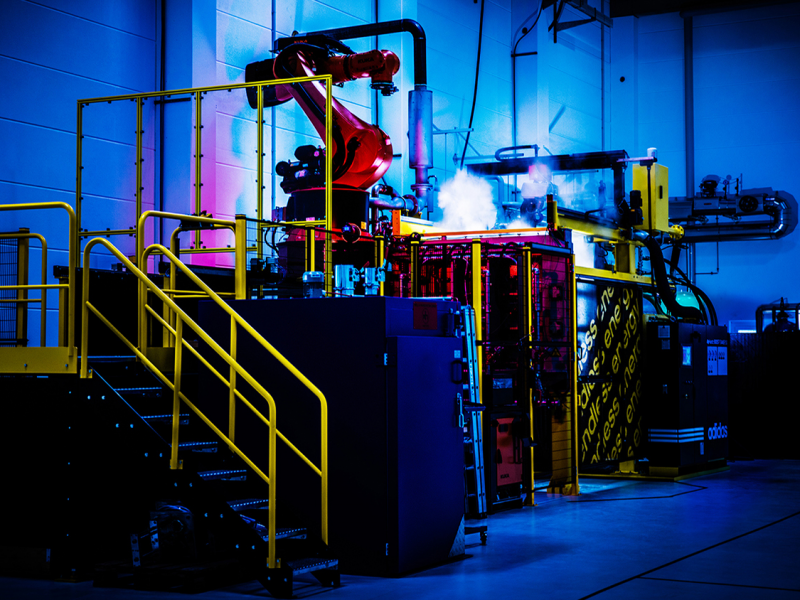

- Adidas‘ Speedfactory in Atlanta is open, producing shoes like the new AM4NYC limited collection.

- The factory is completely automated, and designed to be able to speedily produce limited runs of customizable product or replenish the hottest product selling quickly during the same season.

- Adidas said it can get shoes to market three times faster in a Speedfactory than with traditional means.

- The Atlanta location is Adidas’ second Speedfactory, with the first in Germany. In conjunction, Adidas said it hopes the two factories can produce one million pairs of shoes a year by 2020.

- Adidas will continue to experiment with the Speedfactories, adding new technology and more automated processes to get to a goal of 50% of shoes made by with speedier methods.

Adidas’ American Speedfactory is open for business.

The 74,000-square-foot facility in Cherokee County, Georgia, outside Atlanta, is now pumping out shoes using a completely automated digital manufacturing process.

The first shoes produced and sold from the factory, the new AM4NYC (Adidas made for New York City), created specifically for New York’s urban streets, will go on sale Thursday.

The shoes were made for quickly changing directions on urban streets using Adidas sports-science data, and are an example of the combination of speed and flexibility the new factory offers, as well as its ability to create specific and custom footwear.

As the name implies, the Speedfactory is about speed

"We have ambition to have 50% of our sales [from] under what we call speed programs," Gil Steyaert, an Adidas executive board member responsible for global operations, told Business Insider. "That means that product, which would be reproduced or created in the season [is] for the same season."

The speed initiative is "very much aiming at the fast fashion model where we can bring product closer to the consumer," Steyaert said.

Closer to the consumer also means physically closer - that is, produced in North America, not Asia, where the majority of Adidas shoes are made. That makes it much quicker to ship the shoes throughout the continent, and the shoes can be made specifically for the American market, which has been the major focus for the brand and part of its stellar performance in the last few years.

The Speedfactory is fast, but flexible

The Speedfactory can create more inventory for a hot shoe that's flying off shelves and can't be kept in stock, supplementing other inventory shipped over from Asia. Or the factory can create entirely new shoes specifically for the market as part of a limited run.

Eventually, Steyaert says customers may be able to create their own completely custom, one-of-a-kind Adidas shoes designed to their own specifications online. Things like patch placement and details on the uppers of shoes would be able to be customized.

"Speedfactory is able to customize the shoe indefinitely while being in an automated engineering process," Steyaert said. "We can actually tune the shoe to the customization that the consumer wants to have. That's the goal: full customization, but without compromise on speed."

The fully automated factory means shoe specifications can be changed quickly.

"It's customization without compromising the needle on the speed nor on the changing of the line," Steyaert said. "If you had to make a new line [with traditional manufacturing] you'd have to stop the production line and reproduce."

Adidas has lofty goals for its Speedfactories

The apparel giant wants to create a total of one million shoes a year from both of its two Speedfactories - the Atlanta location as well as the first in Germany - by 2020.

That number is significant, but it's small compared to the total number of shoes Adidas makes each year - 403 million pairs of shoes in 2017, or more than a million a day on average.

The Speedfactories are meant to be "complementary to our main source of supply," Steyaert said. "[They] will never substitute our main source of supply."

As of now, the factory currently has about 150 employees. That relatively low number means it is economically feasible to have a factory in a country without an employee base full of highly skilled shoemakers.

Adidas wants to increase its speed in other ways

The second part of Adidas' speed strategy relates to infrastructure - something that's been under pressure in the US as Adidas' popularity has taken off, particularly distribution.

"When you grow more than 30% per year you push inevitably some infrastructure," Steyaert said.

Adidas has made investments in its East Coast and West Coast warehouses, including its own warehouse in Spartanburg, South Carolina.

The brand is also planning to open a brand new warehouse in New Jersey dedicated to e-commerce and retail. Steyaert says this will be able to service New York City - one of Adidas' "key cities" - with quick delivery, possibly even same-day.

Adidas isn't done with its Speedfactories, however. It plans to innovate within them to add more automated processes and see if it can get even more speed and flexibility out of them. There are currently no plans to create more factories, but Steyaert says he hopes to eventually duplicate its automated technology or even export the technology tested in the Speedfactories to its locations in Asia.